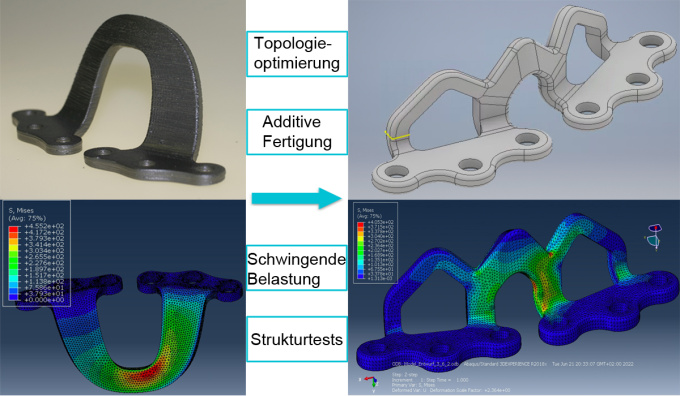

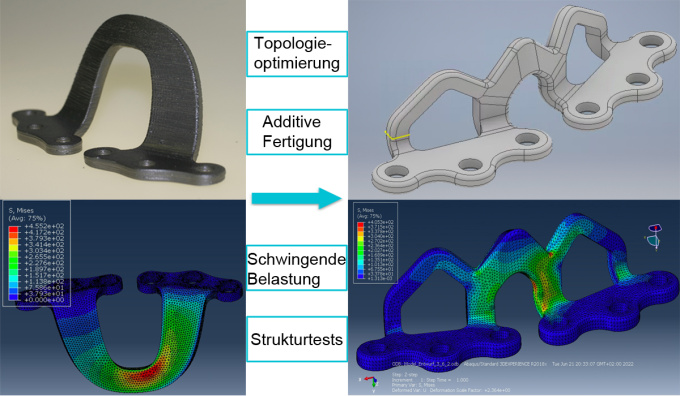

Development and experimental validation of a topologically optimized additively manufactured human symphysis implant

Prototype of an alternative implant of the Basel University Hospital, additively manufactured by Hereon (left). Topology-optimized design (right). Images: Hereon/T. Eberl

ZHM research project

Since August 2022, ZHM has been supporting a joint research project of the Institute for Structural Mechanics in Lightweight Construction (SML) at the Hamburg University of Technology (TUHH) and the Institute for Metallic Biomaterials, Department of Powder-Based Material Development, at the Helmholtz Center Hereon GmbH (Hereon) to develop a new type of implant of the human symphysis. Until now, when the symphysis is fractured, the pelvis has been rigidly fixed with an implant until it heals. This frequently leads to fractures in the implant or to loosening screw connections. In the funded joint project, therefore, a topology-optimized implant is to be developed that can both bear the high mechanical loads and exhibit high biocompatibility. Within the framework of the project, the developed structures are to be manufactured from titanium or magnesium using additive manufacturing and finally subjected to static and dynamic mechanical tests.

With start-up funding from the ZHM, the project can now be supported by materials, students and scientific assistants until the end of the year.